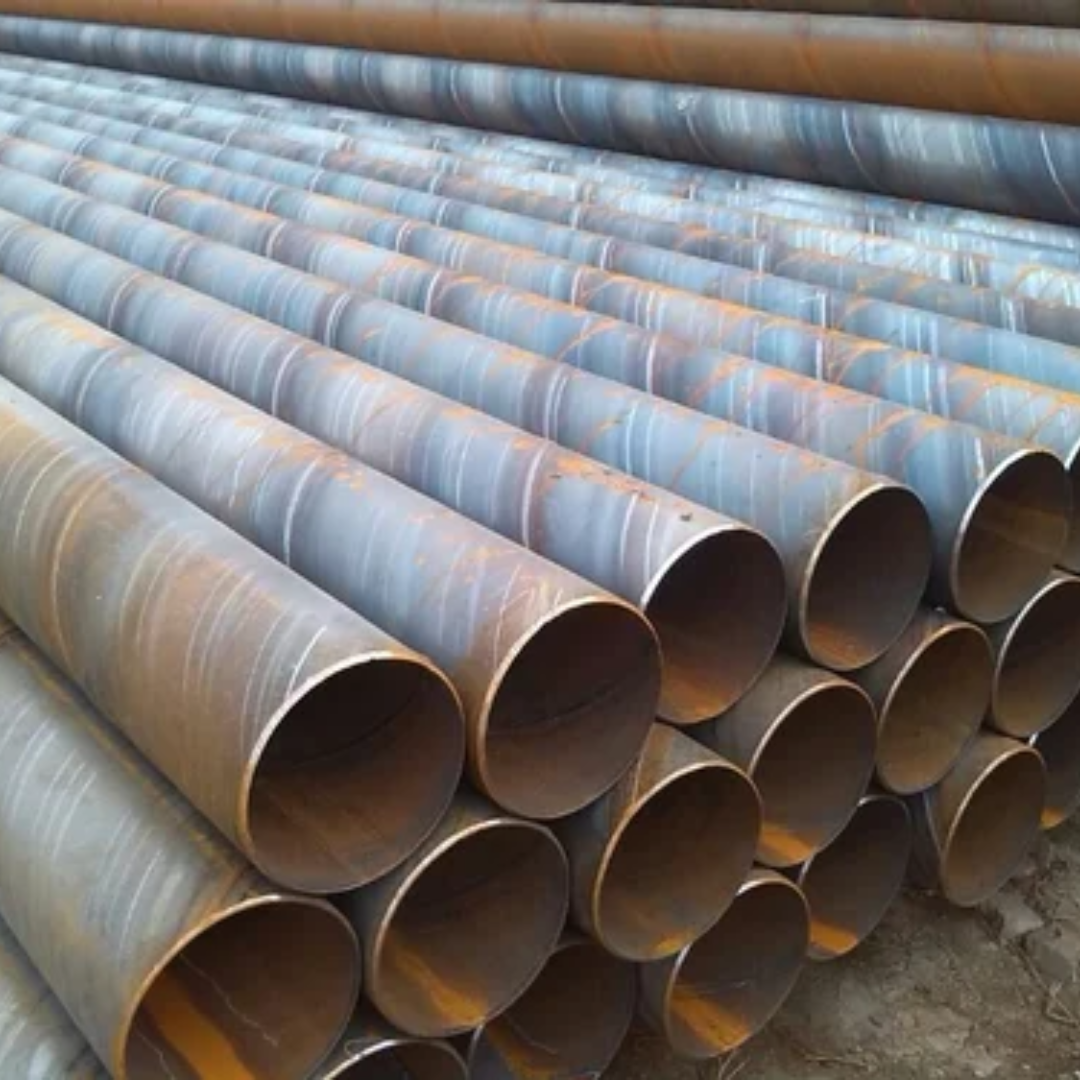

Spiral Welded Pipes

Spiral welded pipes are made by spirally winding a steel strip into a cylindrical shape and welding it continuously along the seam. This manufacturing process allows for the production of large-diameter pipes and provides flexibility in pipe dimensions and lengths.

Grades:

- API 5L:

- Grades X42, X46, X52, X56, X60: Suitable for oil and gas pipelines.

- ASTM A252:

- Grades 1, 2, 3: Used for piling and structural applications.

- ISO 3183:

- L245, L290, L360: For natural gas and petroleum pipelines.

Sizes:

- Nominal Pipe Size (NPS): Typically ranges from 16 inches to 100 inches

- Wall Thickness: Varies based on diameter and application requirements

Applications:

- Oil and Gas: Ideal for large-diameter pipelines transporting oil, gas, and other fluids.

- Water Supply: Used in major water distribution systems and infrastructure projects.

- Structural Supports: Employed in large-scale construction projects, including bridges and buildings.

Spiral welded pipes are valued for their ability to handle large diameters and custom lengths, making them suitable for various heavy-duty applications in infrastructure and industrial projects.

Reviews

There are no reviews yet.